Tubing Connection Refurbishment

Workstring tubing connections are notorious for wearing out quickly, especially when they aren’t hardbanded. In addition, their two-step connections often require up to half the threads to be cut-off before rethreading. This leads to worn upsets with few recuts, a two-tiered issue.

The technology underlying Heatless Welding Solutions was originally invented to address this very problem. With Arnco’s patented low heat input welding process, these tubing connections can be repaired like never before.

- Rebuild tubing connections by adding weld material beyond nominal OD

- Rethread the connection and machine the OD and taper

- Extend tubing upsets by adding weld material to the tube and taper

- Maintain mechanical integrity, including tensile and torsional capacity

Tool Joint Rebuild

Even with hardbanding, tool joints on drill pipe can still wear down. The acceptable ODs for these tool joints are tightly controlled by industry standards, so once a tool joint is worn too much, the whole joint of pipe has historically been rejected. Until now.

Just like with workstring tubing connections, Arnco’s Heatless Welding Solutions can be used to completely rebuild a tool joint, even welding on the threads.

- Rebuild worn tool joints by adding multiple layers of weld material

- Machine to proper OD

- Ensure HAZ does not impact threads

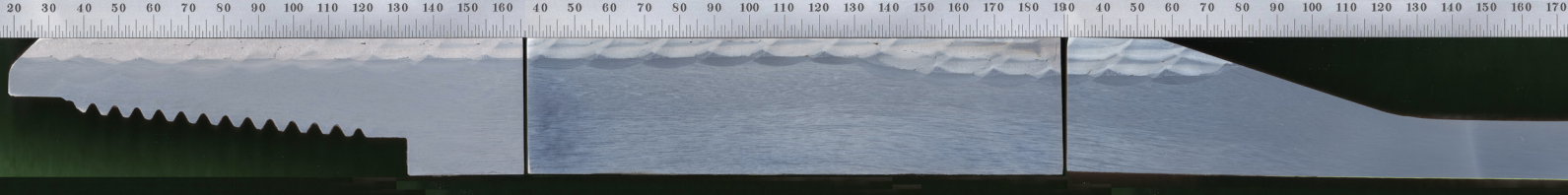

Slip Cut Repair

If worn connections aren’t bad enough, a single deep slip cut or gouge in the tube body of tubing or drill pipe can cause the whole joint to be downgraded or even rejected. Tube bodies are so very thin that it has never even been considered to repair them with welding. Yet Arnco’s Heatless Welding Solutions inputs so little heat during welding that targeted repairs can be done to remove slip cuts and gouges and return the pipe to its original state.

- Inspect the tube body to ensure there are no cracks and that it can be repaired

- Grind rejectable damage out of the tube body

- Re-inspect the tube body for cracks that could have been missed

- Perform targeted welding of the ground area

- Use Arnco’s High Output Grinder so that the weld material is flush with the base material

- Ensure the repaired area is acceptable with another thorough inspection

Heatless HardBanding

Want to Know More?

For more information download our Product Data Sheet.