Hardbanding FAQ

General Hardbanding Questions

Hardbanding is the process of depositing a layer of super hard metal onto drill pipe tool joints, collars and heavy weight drill pipe in order to protect both the casing and drill string components from wear associated with drilling practices.

The Petroleum Industry Glossary:

“Hardbanding is the process of laying on a coating or surface of [super-hard metal] on a [softer metal part] at a point or on an area of severe wear or abrasion – putting a hard surface on a softer metal by welding or other metallurgical process.”

Where it may be impractical or prohibited by structural constraints to manufacture a part from the harder metal, hard-surfacing of the part is a practical solution. Hardbanding is the term given to hardfacing drill pipe – hardbanding is a specific form of hardfacing.

Hardbanding is most commonly applied using a modified MIG welding apparatus designed specifically to apply hardbanding onto a tubular surface. With this process, a continuous consumable wire electrode is fed through a welding torch. Most hardbanding wires require use of shielding gas in order to protect the arc during welding. An electric arc created between the wire electrode and parent metal melts the hardbanding wire, transfers it to the substrate and forms a metallurgical bond between the two alloys. There are other hardbanding application methods that are occasionally used including laser and plasma arc processes.

Where can I find information about hardbanding equipment?

For more information on hardbanding equipment, please see the Hardbanding Equipment section of our website.

Arnco Products

The Arnco 100XT™ and 300XT™ have stood the test of time and proved to be some of the world’s most popular and high performance hardbanding alloys. Arnco has continued its committement to delivering superior, high-performance products, and has since developed Arnco’s Next Generation line of high-performance hardbanding alloys including the Arnco 150XT™ and Arnco 350XT®. For a more detailed look at how these alloys compare, please see the Products Home.

Wear Testing

Wear testing requirements are included in API Specification 7CW. API . This process utilizes a machine that takes hardbanded tool joint and simulates drilling conditions against a casing sample over a period of eight hours. Throughout the duration of the test, measurements related to tool joint and casing wear are recorded and used to derive a number of useful figures.

The most commonly used measures for hardbanding performance are Casing Wear %, Tool Joint Wear in Casing and the ASTM G65-A Dry Sand Abrasion Test. An ideal hardbanding alloy willhave a low Casing Wear %, Tool Joint Wear in Casing and G65-A (grams lost).

Casing Wear % is a measure that indicates the percentage of casing wall material that has worn away during the 8-hour wear test. These figures can range from as little as 3-4% for very casing friendly hardbandings, and up to 100% for total casing failures. Arnco’s line of products range from approximately 2.58-7.28% Casing Wear on the Mohr Engineering Casing Wear Test using a T-95 casing sample and other standardized parameters.

ASTM G65-A test results include the amount of material lost during the test in milligrams (mg) or grams (g). So, for example, Arnco 350XT, one of the most durable products on the market falls within a range of 0.16-0.21 grams lost using standardized parameters of 30 lbs. of side load and 6,000 revolutions.

Applying Arnco Products

For information on becoming an Arnco Certified Applicator please contact Arnco directly or use our online submission form.

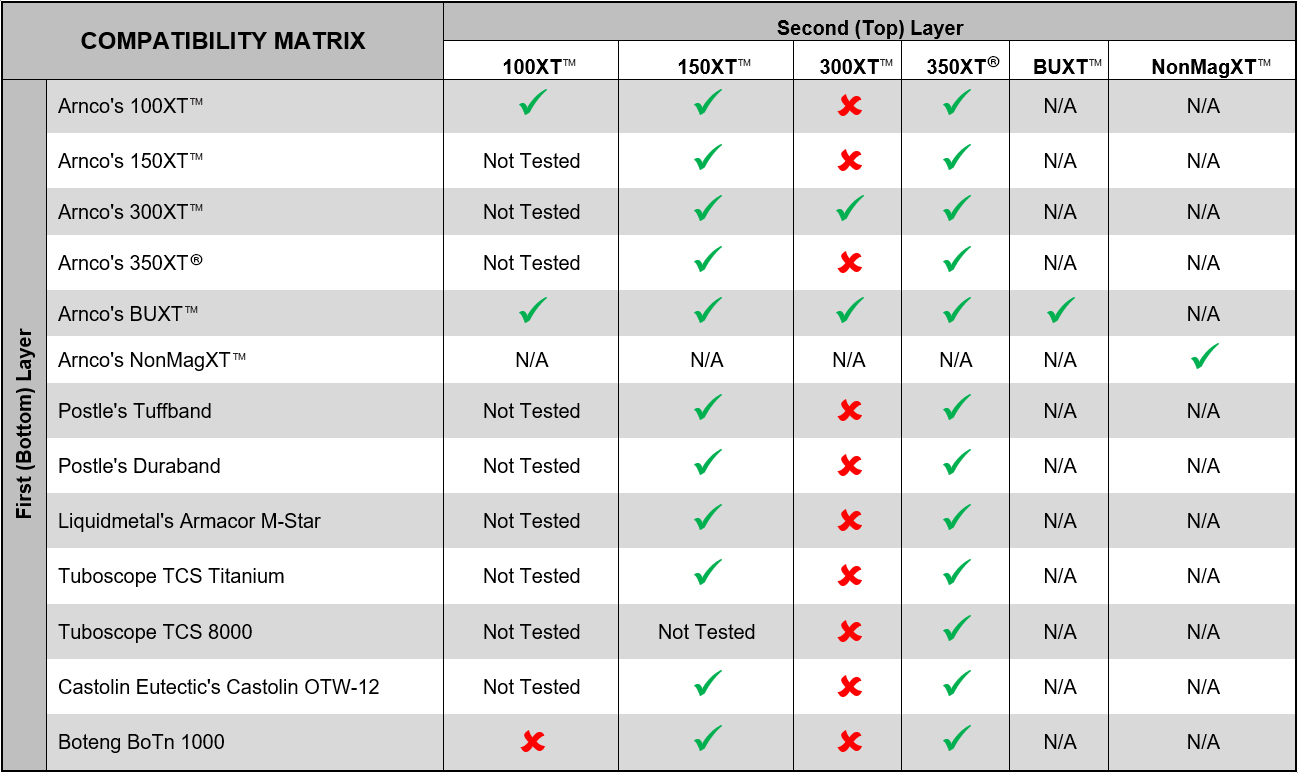

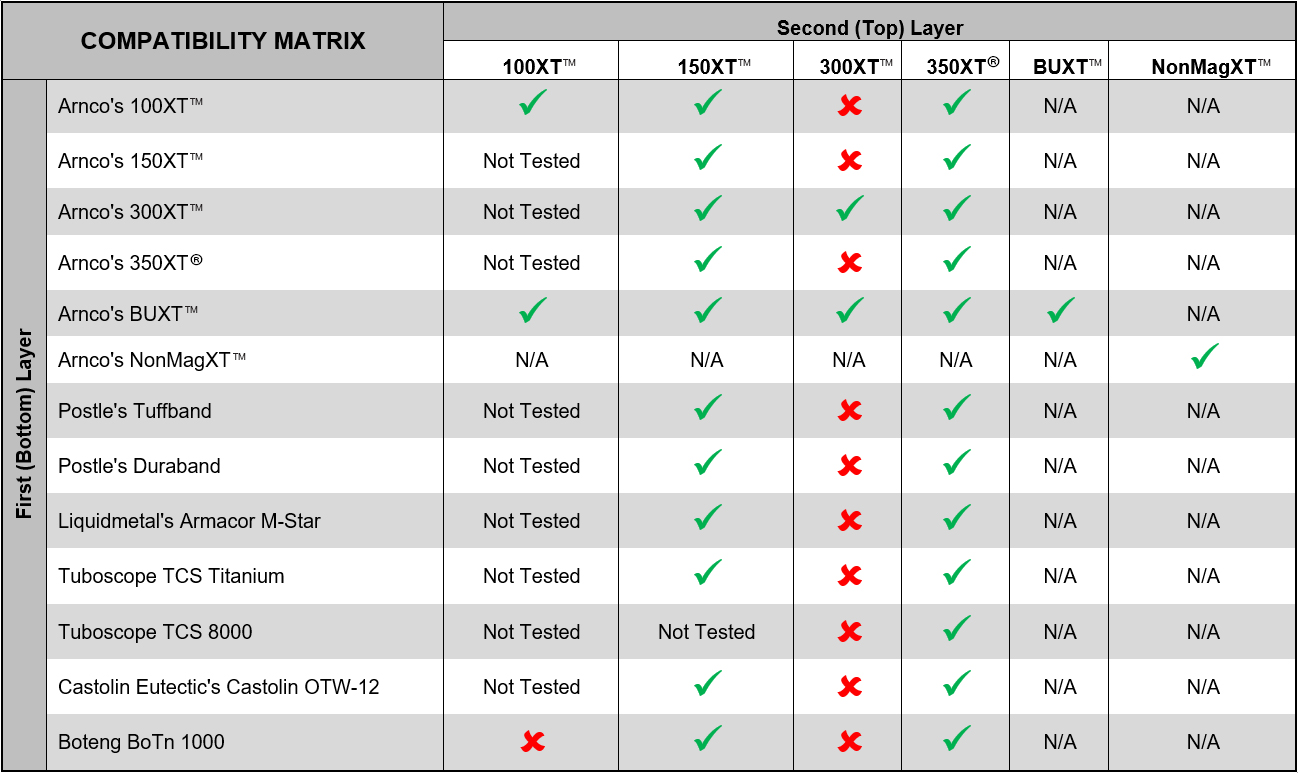

Arnco has conducted extensive compatibility testing of Arnco products over competitive hardbanding materials, which is included in the table below.

Hardbanding Application

Hardbanding products can generally be divided up into two categories: tungsten carbide (non-casing-friendly) and casing-friendly hardbanding products. Casing-friendly material can be metallurgically classified as “chromium carbides”, “titanium carbides” and “niobium borides”. These forms of hardfacing applied to drill string components vary greatly across application and performance characteristics. It’s very important for end users of hardbanding products to become familiar with not only how a hardbanding product can be expected to perform downhole, but also the initial application and re-application characteristics associated with a specific product.

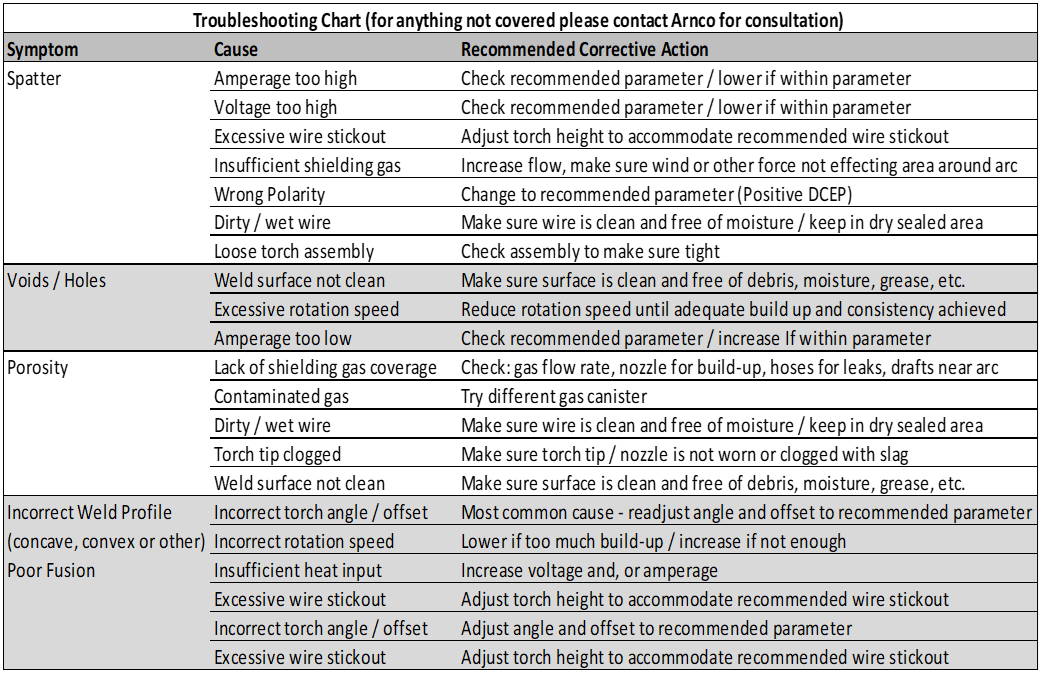

Arnco has developed an extensive history of troubleshooting expertise, some of which are included in the table below.

Due to a large variation in drilling practices, formation abrasiveness and casing materials used, re-application cycles can vary greatly. Typically, once a raised hardbanding has worn flush with the tool joint surface, re-application is necessary. Therefore, it is important to perform regular visual inspections of tool joints during tripping operations.

Hardbanding performance plays a critical role in the frequency of re-application. Using benchmark tests, such as the ASTM G65-A Dry Sand Abrasion Test, can be useful to gauge relative wear resistance of one product against another. Some hardbanding products, such as the 350XT® can be many times more wear-resistant than other Arnco and competing products, requiring fewer re-applications. It is important to consider wear resistance, casing wear, ease of re-application and price when selecting a hardbanding product.

Why Choose Arnco?

Arnco’s hardbanding products were designed to be non-cracking, high performance alloys that cover the spectrum of wear protection needs by end-users. Whether focused on casing wear reduction or drill string life extension, use of Arnco’s hardbanding products produce real economic benefits for pipe owners and well operators.

As an industry standard, Arnco is used by hundreds of operators, drilling contractors and pipe rental companies worldwide. Arnco hardbanding products are specified and used in every active drilling region around the world, and have become the longest standing and most widely used hardbanding products on the market.

- Most compatible products in the market

- Crack-Free

- Designed using advanced computational science

- Re-application without previous layer removal

- Industry-best casing and tool joint protection

- Easy application and excellent weldabilty